- Enabling Pollution Control Through Energy Conservation

Case Studies

- Home

- Case Studies

We are Manufacturer, Supplier, Services Provider of Waste Heat Recovery Hot Water Generation, Waste Heat Recovery Thermic Machine Fluid Heating System, Air Pre Heater / Recuperator, Air Pre Heater on 7.5 Milion HTM Heater, Secondary Air Pre Heater for HTM Heater, Shell And Tube Heat Exchangers, Radiator, Candle Drying Tank, Multilouver Damper For Coal Heater Flue Gas, Total Condensor, Force Circulation Reboiler C-101 ( Heat Exchanger), Polycondensation Byphenyl Evaporator, Biomass Briquette Fired HTM, Compressor Heat Recovery System, Compressor Heat Recovery System, Agitator Tank-Toner System, L P Dryer (Finned Tube Type), Thermic Fluid Filtration System, Finned Tube Assembly Heat Exchanger, Heat Pump, Thermax Make Briquette Fired Steam Boiler from Pune, Maharashtra, India.

One more success project on melting furnace exhaust heat recovery at SSWL

Waste Heat Recovery Hot Water Generation

| EQUIPMENT NAME | Waste Heat Recovery System - Hot Water Generation for Washing M/C. |

| Client | Maxion Wheels Aluminium India Pvt. Ltd. Khed City, Pune. |

| Flue gas I/L Temp. | 200 Deg. C |

| Flue gas 0/L Temp. | 120 Deg. C |

| Heat Recovered | 300,000 Kcal/Hr |

| Heat Recovery used | Hot Water @ 90 Deg. C to Washing Machines |

| Simple ROI | 15 Months |

Waste Heat Recovery Thermic Machine Fluid Heating System

| EQUIPMENT NAME | Waste Heat Recovery Thermic Machine Fluid Heating System |

| Client | Rockman Industries Ltd. Bawal |

| Flue gas I/L Temp. | 350 Deg. C |

| Flue gas 0/L Temp. | 150 Deg. C |

| Heat Recovered | 1,10,000 Kcal/Hr |

| Heat Recovery used | Hot Air @ 160 Deg. C to Top Coat Oven |

| Simple ROI | 15 Months |

Air Pre Heater / Recuperator

| EQUIPMENT NAME | Air Pre Heater |

| Flue gas I/L Temp. | 220 Deg. C |

| Flue gas 0/L Temp. | 110 Deg. C |

| Heat Recovered | 1,70,000 Kcal/Hr |

| Heat Recovery used | Hot Air @ 145 Deg. C to To Oven |

| Simple ROI | 9 Months |

Air Pre Heater on 7.5 Milion HTM Heater

| EQUIPMENT NAME | Air Pre Heater on 7.5 Milion HTM Heater |

| Client | Bhilosa Industries Pvt. Ltd. , Silvasa |

| Flue gas I/L Temp. | 375 Deg. C |

| Flue gas 0/L Temp. | 215 Deg. C |

| Air I/L Temp. | 90 Deg. C |

| Air O/L Temp. | 280 Deg. C |

| Heat Recovery used | Hot Air @ 285 Deg. C |

Secondary Air Pre Heater for HTM Heater

| EQUIPMENT NAME | Secondary Air Pre Heater for HTM Heater |

| Client | Sanathan Textiles Limited, Silvassa |

| Flue gas I/L Temp. | 220 Deg. C |

| Flue gas 0/L Temp. | 135 Deg. C |

| Air I/L Temp | 30 Deg. C |

| Air O/L Temp. | 115 Deg. C |

Process Equipment's ( MOC-SS )

Shell & Tube Heat Exchangers

Shell & Tube Heat Exchangers

Candle Drying Tank

Candle Drying Tank

| EQUIPMENT NAME | Shell & Tube Heat Exchangers, Radiator, Candle Drying Tank |

| Client | Bhilosa Industries Ltd., Silvasa |

Multilouver Damper For Coal Heater Flue Gas

| EQUIPMENT NAME | Multilouver Damper For Coal Heater Flue Gas |

| Client | Garden Silk Ltd. |

| Size | 2000x900 MM |

| MOC | CS,SA 516 GR. 70 |

| Operation | Manual Gear Operated |

Total Condensor

| EQUIPMENT NAME | Total Condensor | |||||

| Client | Sumeet Industries Ltd., Kim, Surat | |||||

| Design Code | ASME SEC VIII DIV.I TEMA CLASS C | |||||

| Tube Side | Shell Side | Tube Side | Shell Side | |||

| Design Pressure | 5 kg/cm2 | 3 kg/cm2 | operating pressure | 3 kg/cm2 | 1 kg/cm2 | |

| Design Temp. | 230°C | 230°C | operating temp. | 205°C | 230°C | |

| Hydraulic Test PR. | 8 kg/cm2 | 5 kg/cm2 | Material | SS304 L Dish End SA516 Gr 70 | SS304 L | |

| Empty Weight | 4700 kg aprox | |||||

| Mfg. Year : March 2022 | ||||||

Force Circulation Reboiler C-101 ( Heat Exchanger)

| EQUIPMENT NAME | Force Circulation Reboiler C-101 ( Heat Exchanger) | |||||

| Client | Shree Durga Syntex Pvt. Ltd. | |||||

| Design Code | ASME SEC VIII DIV.I TEMA CLASS C | |||||

| Tube Side | Shell Side | Tube Side | Shell Side | |||

| Design Pressure | 4 kg/cm2 | 5 kg/cm2 | Operating pressure | 1.3 kg/cm2 | 2 kg/cm2 | |

| Design Temp. | 260°C | 350°C | Operating Temp. | 205°C | 230°C | |

| Hydraulic Test PR. | 6 kg/cm2 | 7.5 kg/cm2 | Material | SS316 L | SA 516 GR 70 | |

| Empty Weight | 4500 kg APROX | Heat Duty | 12,70,000 KCAL/HR | |||

| MFG. YEAR : November 2021 | ||||||

Polycondensation Byphenyl Evaporator

| EQUIPMENT NAME | Polycondensation Byphenyl Evaporator | |||||

| Client | Shree Durga Syntex Pvt. Ltd. | |||||

| Design Code | ASME SEC VIII DIV.I | |||||

| Design PR.(shell) | 4 kg/cm2 | Design PR.(Tube) | 4 kg/cm2 | |||

| Design Temp.(shell) | 330°C | Design Temp.(Tube) | 330°C | |||

| Media (shell) | VP - 1 Steam | Media (Tube) | T66 | |||

| Heat Transfer Area | 40 M2 | volume | 2.65 KL | |||

| MFG. YEAR : November 2020 | ||||||

Biomass Briquette Fired HTM

| EQUIPMENT NAME | Biomass Briquette Fired HTM |

| Capacity | 20 L Kal Per Hr. |

| Working temp. | 300-325 Deg. C |

| Oil Temp. | 280 Deg. C |

| Fuel Used | Wood / Biomass Briquette |

| Simple ROI | 12 Months |

Compressor Heat Recovery System

| EQUIPMENT NAME | Compressor Heat Recovery System |

| Hot Water Temp. | 60-70 Deg.c |

| Washing M/C Temp. | 50-55 Deg.c |

HWG on Oven Exhaust

| EQUIPMENT NAME | HWG on Oven Exhaust |

| Flue gas I/L Temp. | 280 Deg. C |

| Flue gas 0/L Temp. | 120 Deg. C |

| Heat Recovered | 1,50,000 Kcal/Hr |

| Heat Recovery used | Hot Air @ 90 Deg. C to To Oven |

| Simple ROI | 11 Months |

Agitator Tank-Toner System

| EQUIPMENT NAME | Red & Blue Toner System |

| CLIENT NAME | JINDAL POLYFILMS LTD. NASIK |

| Capacity | 1 M3 Colour Addition System |

L P Dryer (Finned Tube Type)

| EQUIPMENT NAME | L P Dryer (Finned Tube Type) |

| Client | SHREE DURGA SYNTEX PVT. LTD. |

| Tube MOC | Gr SA 179, 19.050D X 2.20 Thk X 730 mm Long End to End width 680 mm finning length |

| Fins | SS 304 |

| Pneumatic Test Pr. | 5 kg/cm2 |

Thermic Fluid Filtration System

| EQUIPMENT NAME | Thermic Fluid Filtration System |

| CLIENT NAME | SHREE DURGA SYNTEX PVT. LTD |

| Oprating Temp | 350°C |

| Oprating Pressure | 6 Bar |

| Flow | 10 CMH |

| Element Moc | SS 304 |

Finned Tube Assembly Heat Exchanger

| EQUIPMENT NAME | Finned Tube Assembly Heat Exchanger |

| MOC Tubes | BS 3059/SS 304/SS 316 |

| MOC FINS | MS CRCA / SS 304 / SS 316 |

| Size | As per requirement |

Heat Pump

| EQUIPMENT NAME | Heat Pump |

| Hot Water O/L Temp. | 75 Deg. C |

| Hot Water O/L Temp. | 85 Deg. C (On Demand) |

Thermax Make Briquette Fired Steam Boiler

| EQUIPMENT NAME | Thermax Make Briquette Fired Steam Boiler |

| CLIENT | DHANSANJIVANI AGRO FEEDS PVT. LTD. |

| Capacity | 1 Ton / Hr. |

| Steam Pressure | 10.54 Kg/cm2. |

| Fuel Used | Wood / Biomass Briquettes |

| Utilization | Steam to Cattlefeed Plant. |

WHRS on Melting Furnace & Chip Melting Furnace Exhaust - Hot Water Generation.

| EQUIPMENT NAME | Melting Furnace & Chip Melting Furnace Exhaust |

| CLIENT | Steel Strips Wheels Limited (Mehsana Gujrat) |

| Exhaust Temp. | 220 Deg. C |

| Fuel Consumption | Propane Gas |

| Heat Recovery | 5,00,000 kcal/hr |

| Saving In Terms of Propane | 45 Kg/Hr |

Energy Conversion :-

Hot Water @ 90 Deg. C To Hot Water Generator .

Pay Back Period : 9 Months.

WHRS on Oven Exhaust - Hot Water Generation.

| EQUIPMENT NAME | Oven Exhaust |

| CLIENT | Mahindra Swaraj Division, (Mohali) |

| Exhaust Temp. | 170 Deg. C |

| Fuel Consumption | PNG |

| Heat Recovery | 2,50,000 kcal/hr |

| Saving In Terms of PNG | 27 SCM/hr |

Energy Conversion :-

Hot Water @ 95 Deg. C To Hot Water Generator .

Pay Back Period : 10 Months.

WHRS on Melting Furnace Exhaust - Hot Water Generation for Casting washing M/C & Casting Impregnation Process.

| EQUIPMENT NAME | Melting Furnace Exhaust |

| CLIENT | Jaya Hind Industries Pvt. Ltd. (PDC-2 PLANT) |

| Exhaust Temp. | 350 Deg. C |

| Fuel Consumption | Biodiesel |

| Heat Recovery | 3,32,000 kcal/hr |

| Saving In Terms of Electricity | 367 kWh |

Energy Conversion :-

Hot Water @ 90 Deg. C to Washing M/C.

Hot Air @ 60 Deg. C To Washing M/C.

Pay Back Period : 9 Months.

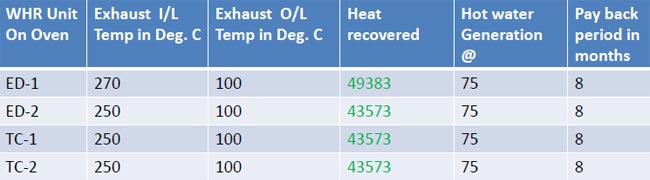

WHR on Burner Exhaust - Hot water for Paint Shop Process.

| EQUIPMENT NAME | Burner Exhaust |

| CLIENT | Kalyani Maxion Wheels Ltd. Chakan |

| Exhaust Temp. | 255 Deg. C |

| Total Heat Recovered | 1,80,103 kcal/hr |

| Saving In Terms of PNG | 20 SCM/hr |

Hot Water @ 75 Deg. C To Hot Water Generator .

Pay Back Period : 8 Months

Air Preheater on HTM Fresh air & hot air.

Client : Bhilosa Industries Pvt. Ltd. Silvasa

• Flue Gas I/L Temp. :– 238 Deg. C

• Flue Gas O/L Temp. :–161 Deg. C

• Fresh Air I/L Temp. :- 20 Deg. C

• Fresh Air O/L Temp. :- 115 Deg. C

• Flue Gas I/L Temp. :– 238 Deg. C

• Flue Gas O/L Temp. :–161 Deg. C

• Fresh Air I/L Temp. :- 20 Deg. C

• Fresh Air O/L Temp. :- 115 Deg. C

Biomass Briquette Fired Furnace Centralized TFH for Multiple Applications

• Capacity :- 20,00,000 Kcal/hr.

• Thermic fluid I/L Temp. :– 260 Deg. C

• Thermic fluid O/L Temp. :– 280 Deg. C

Energy Conversion :-

• Hot Air @120 Deg. C To Oven .

• Hot Air @230 Deg. C To Oven .

• Hot water to Process @90 Deg. C

• Pay Back Period : 15 Months.

• Thermic fluid I/L Temp. :– 260 Deg. C

• Thermic fluid O/L Temp. :– 280 Deg. C

Energy Conversion :-

• Hot Air @120 Deg. C To Oven .

• Hot Air @230 Deg. C To Oven .

• Hot water to Process @90 Deg. C

• Pay Back Period : 15 Months.

WHR System on Furnace Exhaust - HWG

• Working Temp. :– 220 Deg. C

• No. of Furnace :- 4 Nos.

• No. of WHR Systems :- 4 Nos.

• Fuel Consumption :- ( LPG )

• Heat Recovery :- 550000 kcal/hr.

• Saving In Terms of LPG :- 47 kg/hr.

Energy Conversion :-

• Hot Water @ 90 Deg. C To HWG

• Pay Back Period :- 6 Months

• No. of Furnace :- 4 Nos.

• No. of WHR Systems :- 4 Nos.

• Fuel Consumption :- ( LPG )

• Heat Recovery :- 550000 kcal/hr.

• Saving In Terms of LPG :- 47 kg/hr.

Energy Conversion :-

• Hot Water @ 90 Deg. C To HWG

• Pay Back Period :- 6 Months

Compressor Heat Recovery System - HWG

• Saving In Terms Of Electricity :- 60 kWh.

• Energy Conversion :- Hot Water @ 70 Deg. C

• Pay Back Period :- 15 Months

• Energy Conversion :- Hot Water @ 70 Deg. C

• Pay Back Period :- 15 Months

Incinerator Exhaust Whr System - Generation Of Hot Rafinate & Water

• F.G .Working Temp. :– 185 Deg. C

• Heat Recovery :- 6,55,000 kcal / hr.

• Saving In Terms of Steam :- 600 Kg .

• Saving In Terms of NG :- 13 SCM/Hr.

• Energy Conversion :- To Pre-Heat Water And raffinate To 95 Deg. C

• Pay Back Period :- 10 Months.

• Heat Recovery :- 6,55,000 kcal / hr.

• Saving In Terms of Steam :- 600 Kg .

• Saving In Terms of NG :- 13 SCM/Hr.

• Energy Conversion :- To Pre-Heat Water And raffinate To 95 Deg. C

• Pay Back Period :- 10 Months.

Kiln Exhaust Whr System - Generation Of Hot Air

• F.G .Working Temp. :– 400 Deg. C

• Heat Recovery :- 1,18,000 kcal / hr.

• Saving In Terms of LPG :- 11 kg/hr.

• Energy Conversion :- Hot Air through to Oven @ 250 Deg. C

• Pay Back Period :- 17 Months.

• Heat Recovery :- 1,18,000 kcal / hr.

• Saving In Terms of LPG :- 11 kg/hr.

• Energy Conversion :- Hot Air through to Oven @ 250 Deg. C

• Pay Back Period :- 17 Months.

Engine Test Bed Exhaust Whr System – Generation Of Hot Water

• F.G .Working Temp. :– 400 Deg. C

• Heat Recovery @ 100 % load :- 1,68,000 kcal / hr.

• Heat Recovery @ 50 % load :- 84,000 kcal / hr.

• Saving In Terms of LPG :- 8 kg/hr.

• No of Test Beds :- 8 Nos.

• Energy Conversion :- To Heat Washing M/C Tank temp @ 55 Deg. C

• Pay Back Period :- 14 Months.

• Heat Recovery @ 100 % load :- 1,68,000 kcal / hr.

• Heat Recovery @ 50 % load :- 84,000 kcal / hr.

• Saving In Terms of LPG :- 8 kg/hr.

• No of Test Beds :- 8 Nos.

• Energy Conversion :- To Heat Washing M/C Tank temp @ 55 Deg. C

• Pay Back Period :- 14 Months.